Prodtex can support your robot project with offline programming, calibration and commissioning. Our staff have experience from work with robotics projects in automated module manufacturing of houses, heavy welding in shipbuilding, automation of drilling applications with high precision in the aerospace industry as well as numerous projects in arc welding. Our broad expertise in robotics will provide full support for the introduction of robotics into your production.

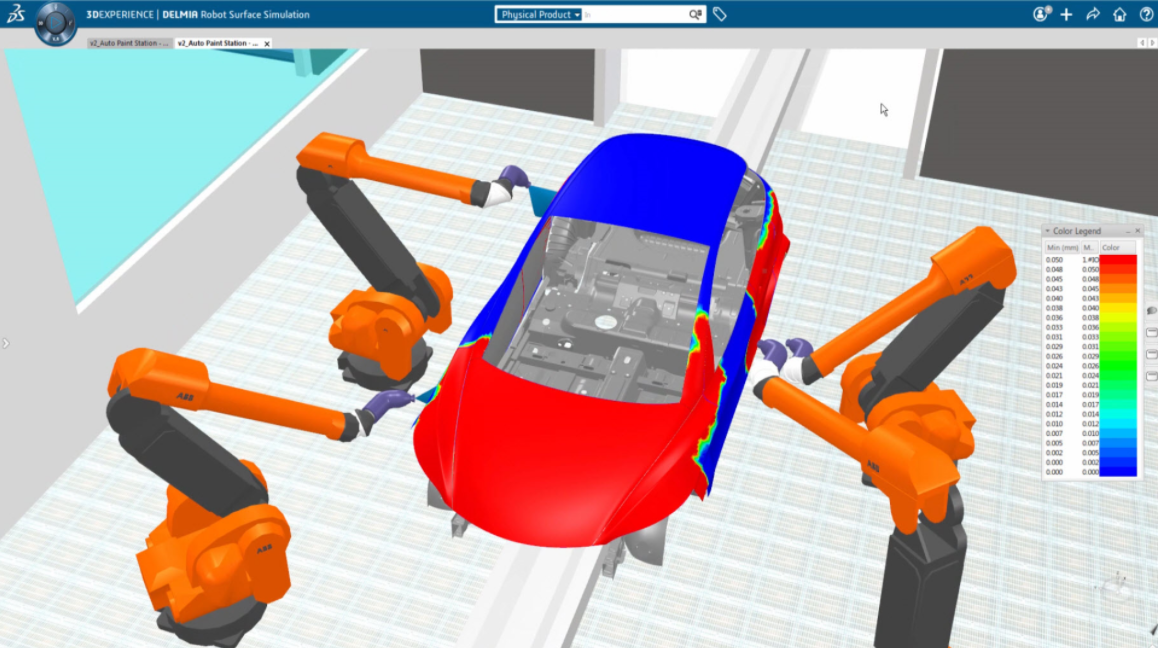

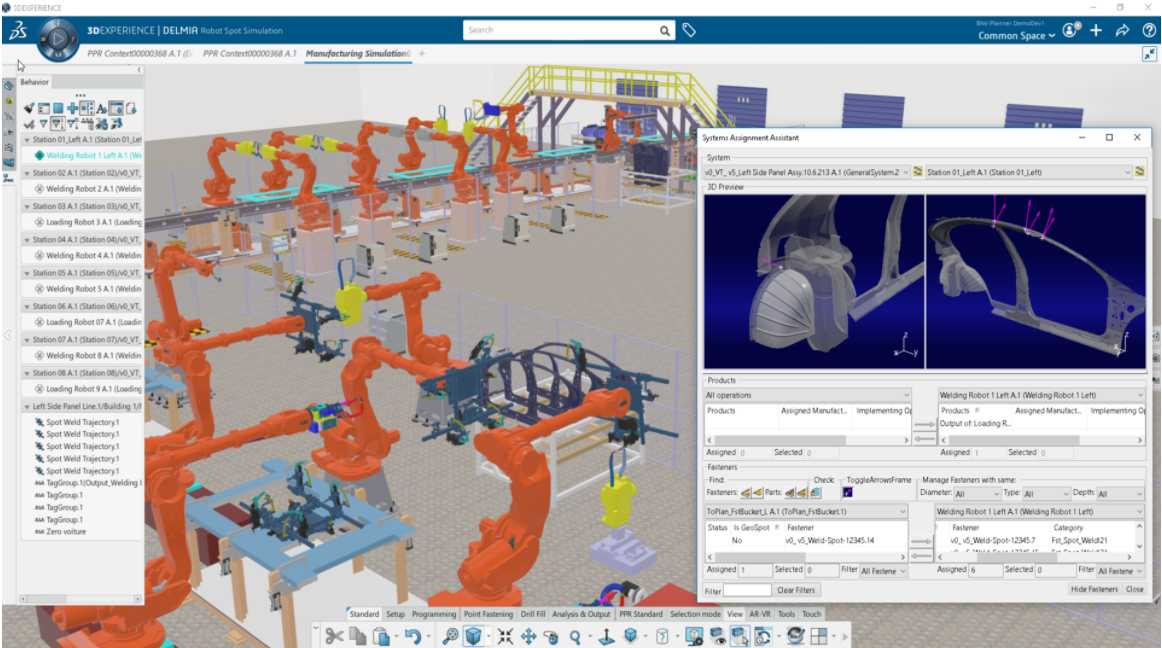

By building a 3D model of a robot station and thus visualising the intended station, many questions are answered. To what height should the robot be located? What type of positioners should be used? Which welding gun should be used? The ability to utilise simulations will improve communications and facilitate problem solving, with the simulation providing moving images of the planned design solution. Those who are designing the station can manipulate the 3D model to help make fact-based decisions based on visualisations of the installed station.

Another important factor for robot simulation is to avoid late changes to production equipment such as fixtures. This is achieved through product reviews, design inputs into the fixture or testing and verification of the fixture. A 3D model of the fixture is loaded into the assembly simulation, allowing the access for different operations such welding to be checked. Highlighting any access problems before the fixture is even manufactured, this eliminates the costly expense of redesign and manufacture down the line. Without simulation these issues might not be identified until the online programming phase, interrupting the robot station for longer than is necessary.

Online programming steals productive time from the robot. If the company has a robot station with high usage they would want to limit the interruptions for the programming of new products to the bare minimum. Offline programming of the product via robot simulation allows the robot station to continue production during the programming phase. The robot program can even be created before the physical product or fixture is available! This reduces the stop-time at the station, creating a more seeemless robot intergration for a new or modified product that needs to be processed.