Prodtex: 30 Years of Robotic Expertise for Seamless Automation and Simulation

With 30 years of experience in robotics, Prodtex is a top partner for industrial robotic simulation. We provide expert support in offline programming, calibration, and commissioning, backed by experience in sectors such as aerospace, shipbuilding, and modular construction.

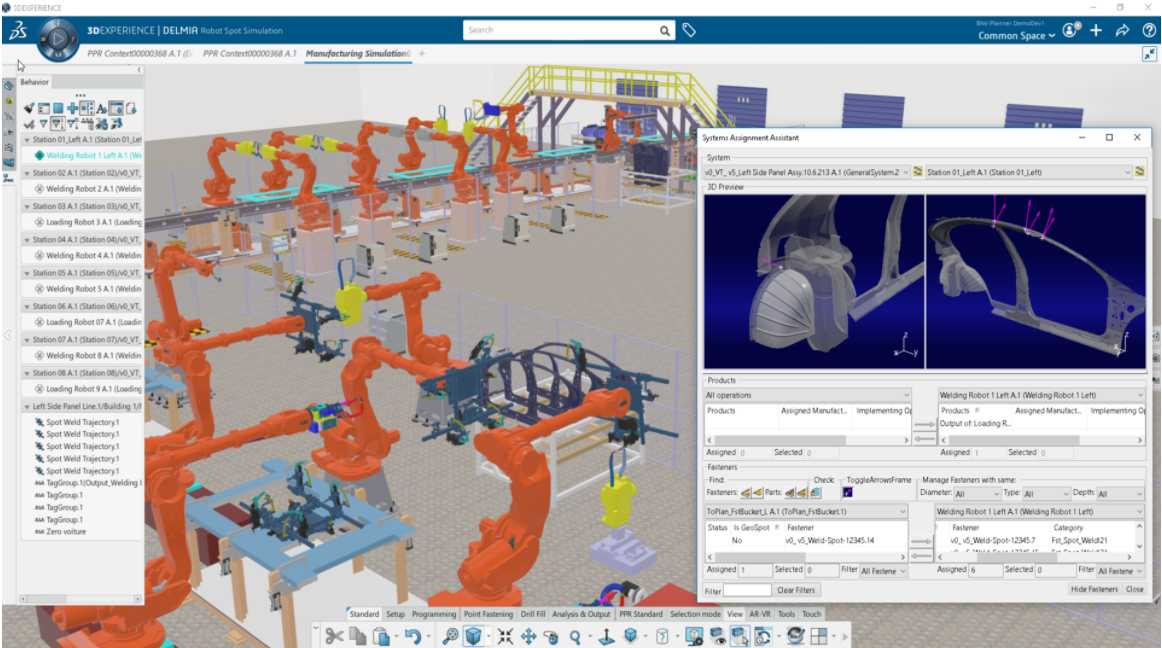

By creating 3D models of robotic stations, Prodtex enables precise planning, answering critical questions about robot positioning, tooling, and setup. These simulations improve communication and facilitate decision-making based on visual insights, reducing the risk of costly design changes.

Simulation also ensures early identification of fixture access issues, preventing expensive late-stage modifications. Additionally, offline programming allows robot stations to remain productive while new programs are developed, minimizing downtime. This method even enables robot programs to be prepared before physical products or fixtures exist, ensuring seamless integration.

Key Points:

- Expertise & Experience: 30 years in robotics across multiple industries.

- Simulation for Optimization: 3D models improve planning, communication, and problem-solving.

- Efficiency & Cost Reduction: Offline programming minimizes downtime and late-stage changes.

Prodtex Introduces the 3DExperience Add-in for RobotStudio

Prodtex has launched the 3DExperience Add-in for RobotStudio, enabling seamless integration between RobotStudio and 3DExperience for advanced robot simulation and control.

The Virtual Robot Control (VRC) feature supports Realistic Robot System (RRS), allowing ABB controllers in RobotStudio to execute simulations within 3DExperience. This ensures highly accurate motion and cycle control for RAPID programs, running in RobotStudio while simulating robots in 3DExperience. Users can execute RAPID programs via the RobotStudio interface or the robot’s native Teach Pendant.

In early project phases, RAPID programs are translated into DELMIA’s standardized language to enable a system-level simulation. However, closer to deployment, robot-specific commands, I/O signals, and PLC programming require a more detailed RAPID execution. The Add-in facilitates direct RAPID programming while continuing simulation in 3DExperience without rebuilding the digital twin.

The Add-in supports OPC UA communication, enabling bidirectional signal exchange between RobotStudio and 3DExperience via an OPC server, keeping signal values synchronized across the simulation.

Additionally, 3DExperience offers a user-friendly logic programming interface with conditional statements and I/O signal creation, useful for multi-robot simulations and interlocking analysis.

This Add-in enhances efficiency in digital factory simulations, especially for frequent product updates and system integration.

Contact: henrik.kihlman@prodtex.com for more information

Ship Manufacturing Automation

Prodtex is a provider of automation solutions for Ship building. We provide solution to plan the ship manufacturing production by delivering 3DExperience for marine and offshore industry. We have customized solutions to streamline the process from importing the CAD models from design partners all the way to robots programmed on the workshop floor.