The Norweigan University of Science and Technology – NTNU, based in Ålesund, decided to utilise Dassault Systemes 3DEXPERIENCE software at the start of 2017. The first course taught using 3DExperience was virtual production within lean manufacturing, robot simulation and the design of future factories. The education course uses the Dassault Systéme 3DExperience platform.

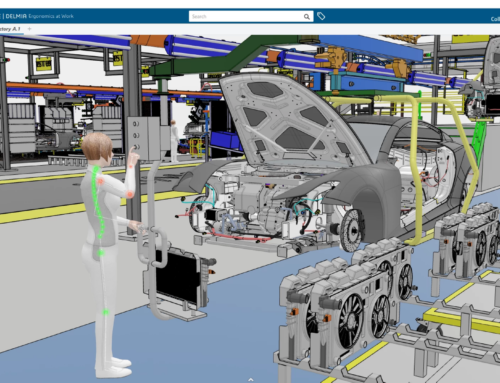

A sustained relationship of collaboration between Prodtex and NTNU led to this decision to deploy the platform on the Industry 4.0 course. The course includes four packages: the first, led by Irina-Emily Hansen, focused on methods within lean thinking within production development. The second module, led by Dr. Henrik Kihlman from Prodtex, includes an introduction on robot simulation. During three full days – the morning sessions detail the theory behind robotics and its applications, and in the afternoon the students work in groups to create a complete simulation of a robot task. The third module in the course, which has not yet started, will cover the basics within process planning, including the practice of taking EBOM structures to MBOM structures. The students will get the chance to design a factory layout. The fourth and last module of the course will cover 3D printing, where 3DExperience has dedicated apps for this purpose.

According to Dr. Henrik Kihlman, the deployment of 3DExperience was very smooth, in large part thanks to the 3DCompanion from Dassault System. The 3Dcompanion is a web based training portal covering the entire range of the 3DExperience platform – anything from product development to project management. Moreover, the cloud based infrastructure is extremely simple since no servers and services need to be installed. The client installation was completed via a VMWare service, so the students did not have to install anything other than VMWare.

Paul Steffen Kleppe, assistant professor in manufacturing at NTNU, was excited to have the opportunity to evaluate VMWare when 60 students all worked on an advanced simulation at the same time. Using a VMWare server based infrastructure the installation only had to be performed once. The students used their own laptops, many used Apple OSX, to do the lab.

Kleven Verft in Ulsteinvik visited during the three-day course for module 2. They took the opportunity to compare their existing Citrix solution which they use for running 3DExperience. Olve Brandal, responsible for CAD and PLM at Kleven Verft, found it difficult to compare the two solutions since Kleven does not yet have as many 3DExperience users as NTNU. Olve thought that the VMWare solution was performing really well.

Ola Jon Mork, responsible for the industry 4.0 initiative at NTNU Ålesund, believes this course is a perfect base to undertake their bachelor projects. It will introduce the students to new production methods and enable transfer of knowledge into the industry once they complete their studies. NTNU in Ålesund will continue with Industry 4.0 within the master program, but with more research focused strategies.

Another part of the workshop was the visit from Simon Sundal, who is responsible for the welding factory at Kleven Verft. Simon held a guest lecture where he proudly showed the development and introduction of industrial robots into the welding process for building ships. Simon also explained how they have brought home large parts of the production from low-cost contrives and explained the most important reason was the automation.

If you want to know more about Prodtex or 3DExperience please contact: Henrik Kihlman – 0731 558102 – henrik.kihlman@prodtex.com.