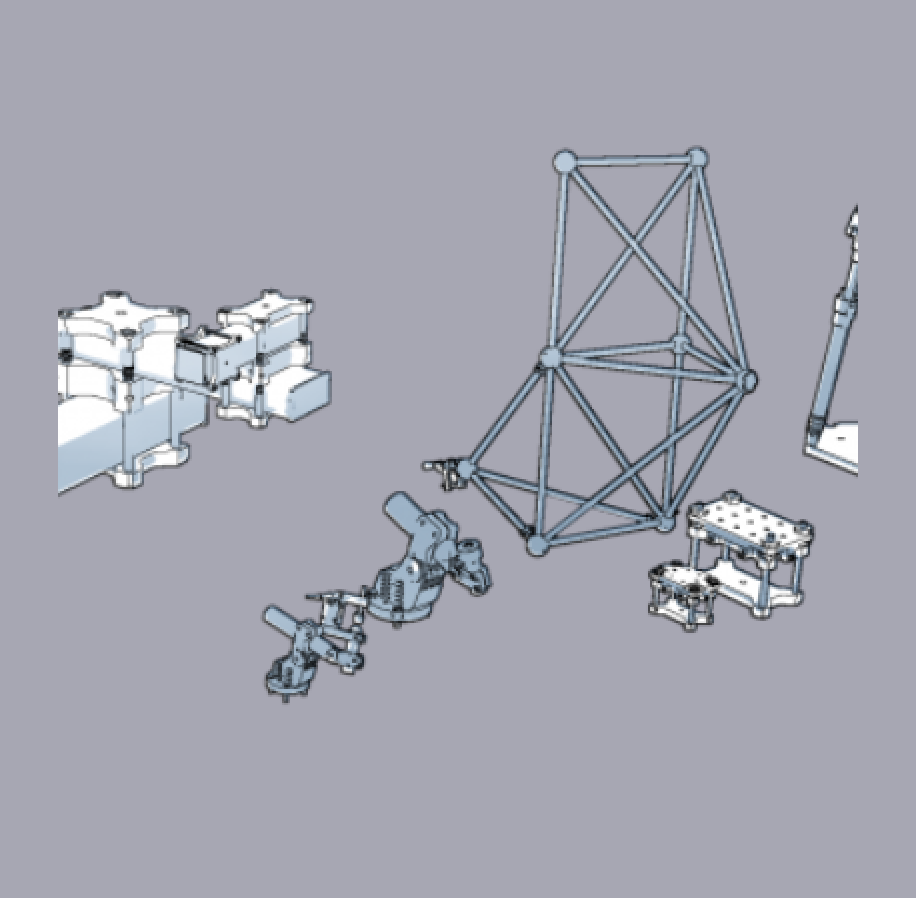

There are many benefits to the use of these flexible systems, some of these are as follows:

- Increases cost efficiency through the re-use of fixture components on multiple projects,

- Reduces fixture design lead times due to the use of dedicated design apps,

- Removes the limitations of traditional fixture design which requires component geometry and datum’s to be locked months in advance of manufacture,

- Cuts fixture build lead times due to the use of off the shelf modular components,

- Facilitates single piece flow on multi product processes.

Innovative manufacturing

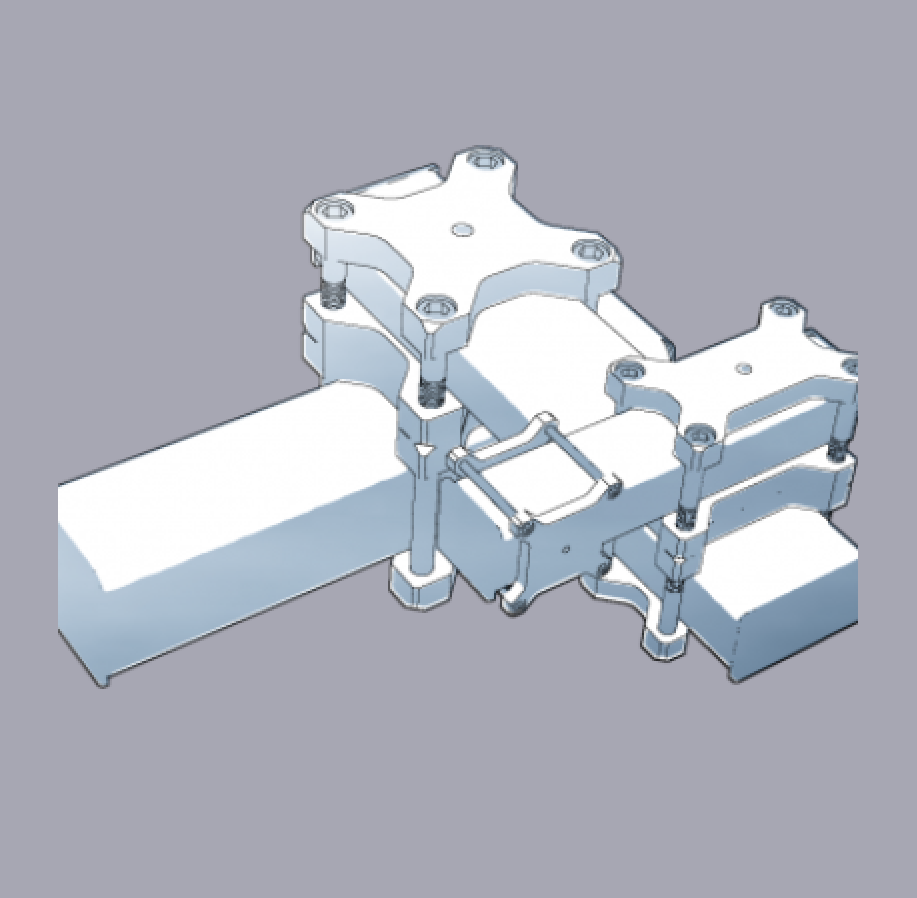

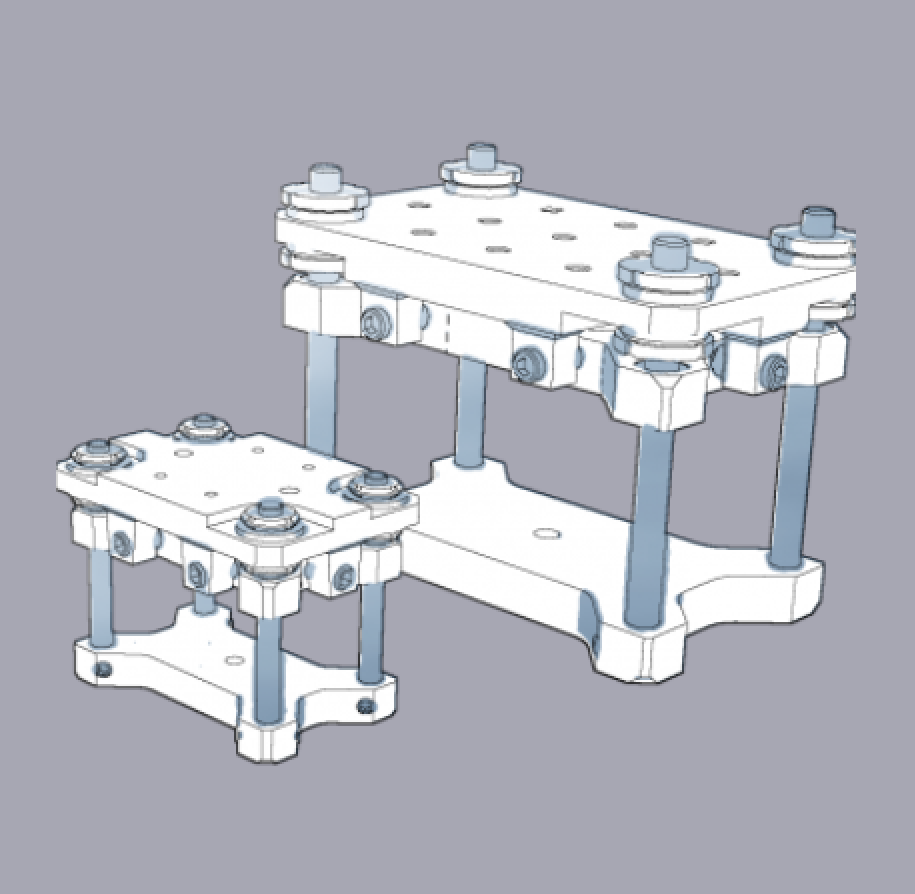

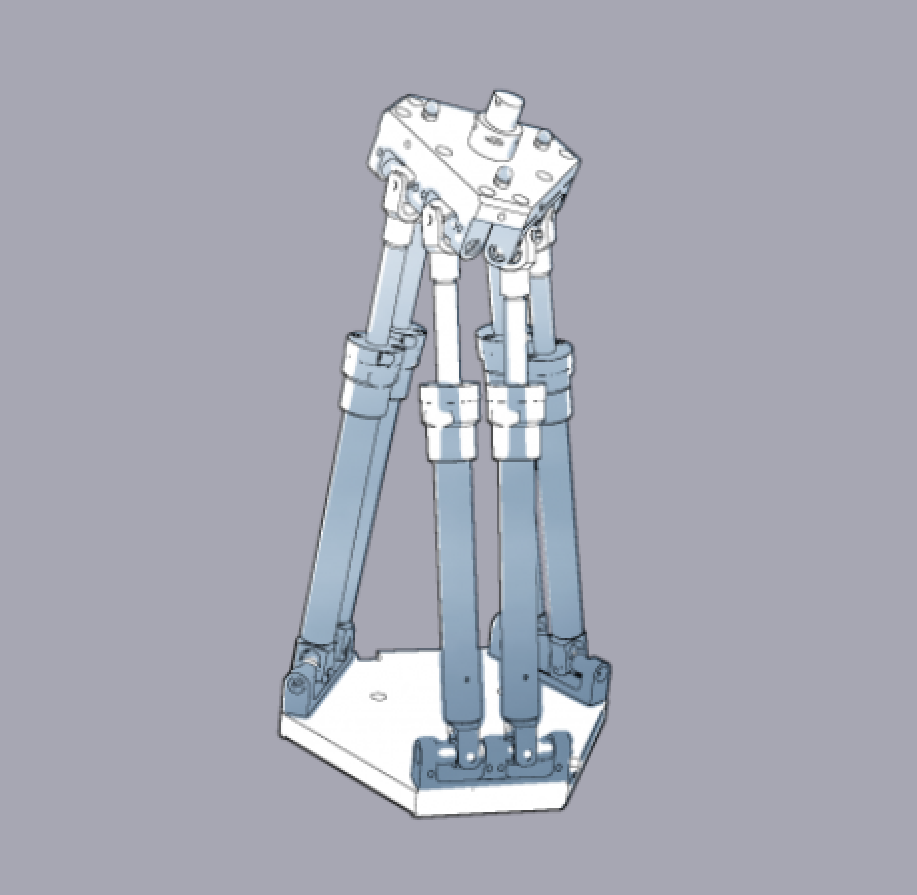

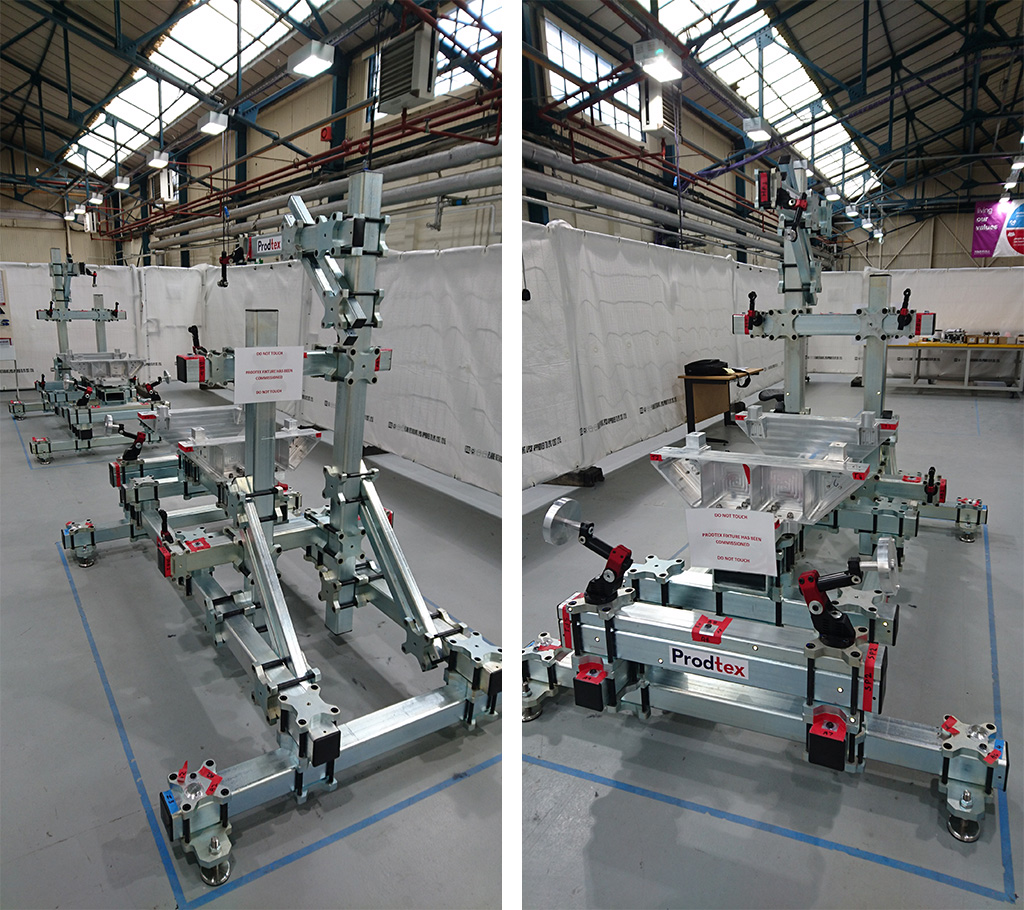

Prodtex utilise a number of different reconfigurable tooling systems, both independently and in conjunction with each other in order to provide the optimum solution to meet our clients needs.

Some of the tooling solutions that we offer are as follows:

Re-configurable Tooling can also be refered by the following names within the industry:

- Flexible Tooling

- Flexible Fixtures

- Adaptable Tooling

- Modular Fixtures

- Configurable

- Re-Configurable

- Adjustable

- Changeable

- Reproducible

- Rebuild able

- Modular

- Reconfigurable tooling

- Reconfigurable Fixtures

“The ability to rapidly re-configure tools and fixtures to adapt to multiple products, fluctuating build rates and variability in the condition of supply of sub component parts offers huge potential to increase the efficiency of assembly operations” — Andy Silcox, the MTC’s Technical Specialist (Assembly Systems)